Nov 28, 2019 4:13:35 PM

Manufacturing Metallic Pigments Manufacturers of pigments and similar..

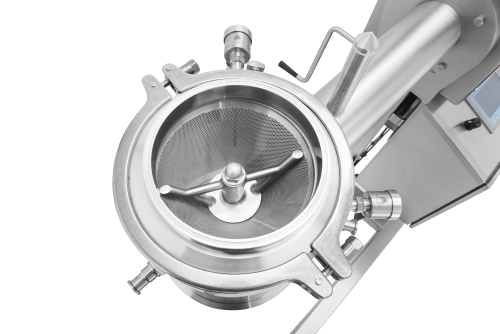

Effective and reliable size reduction machinery designed to stand up to rigorous use no matter what the product characteristics.

When handling chemical materials, there is an essential need to provide operator and process safety at all times as often the products being handled can be highly toxic and difficult to handle.

Chemical powder characteristics can be challenging in the production environment, such as poor flowability, abrasive and corrosive or wet slurry.

Quadro Engineering has extensive experience in providing deagglomeration and size reduction of metal powders without a noticeable temperature rise in the discharged product.

We can recommend the right equipment to improve the efficiencies of your process based on our extensive experience with a variety of materials.

We have many decades of experience processing a wide variety of difficult-to-handle hazardous powders.

Our equipment is particularly well-known for being able to successfully process battery powders, sodium nitrate, Teflon, and Herbicides.

We offer industry-leading milling machines and size reduction equipment for chemical powders and our knowledge has been built over decades.

Our processing experts can help you solve your size-reduction challenges, whilst meeting the strict control standards of the industry.

We understand the needs of the market, especially when it comes to milling chemical or hazardous powders. As materials become more potent the need for containment increases.

Quadro Engineering develops and manufactures a range of powder processing systems for the chemical industry. Our capabilities mean that we can offer equipment to suit a range of requirements.

Recommended downloads for manufacturers of products using chemical powders.

The world's most advanced benchtop multi-purpose powder milling and screening platform.

Innovative milling, sifting and size reduction technology, offering multiple powder processing solutions on one platform.