What to Consider When Choosing Food Powder Processing Equipment

In today's competitive landscape, food and powder beverage manufacturers must find ways to be productive at speed and remain agile and adaptable. To remain competitive, the selection of food processing equipment needs to consider the following:

- ease of operation

- cleaning speed

- maintenance burden

With a keen eye on the bottom line, financial payback on any equipment purchases is a must.

When manufacturing food flavorings and ingredients, raw material sizing is a common processing step. It is vital in food production as it converts raw ingredients into more manageable forms, improving the texture and consistency of the final product and improving the manufacturing flow.

Additionally, during this process step, the size reduction of the materials leads to the extraction of valuable components such as flavors and nutrients. The milling process can be tailored to achieve different particle sizes, affecting the texture and appearance of the final product. For instance, fine milling is typically used for producing flours, while coarse milling is appropriate for items like breakfast cereals or off-spec product rework.

How to Overcome Food Manufacturing Challenges

Depending on the particle size range, material above and below spec is often reworked or scrapped. This process is necessary to reduce waste, maintain consistent formulations and control content uniformity to maintain product quality for consumers.

The obvious need is a food-grade system that can mill material within the correct size range on the first pass — not after the second, third, or fourth attempt.

Mills For Food and Beverage Manufacturers

The Quadro® Comil® has been the ideal choice for decades, delivering high efficiencies and cost savings for food producers.

It has been selected the world over for:

- High Capacity Milling

Achieving 50% more throughput than conventional mills due to Comil’s bulk feeding capability. - Low Heat Operation

Excellent for milling products with low melting points. - Lower Amounts of Dust

Significant cost savings can be achieved by eliminating or reducing dust collection/explosion protection devices. Yields improve and disposal fees are reduced due to minimal product losses. - Low Energy Milling

Up to 60% reduction in energy consumption for similar capacities with conventional mills. - Easy to Clean Machinery

Minimal surface area and easy product flow design ensure units can be cleaned in minutes. - Easy-to-Use Milling Equipment

Simple controls minimize operator training requirements and increase operation accuracy. - Flexible Feed Systems

The infeed can be controlled or bulk-fed eliminating costly, hard-to-clean feeders. - Versatile Setup

A wide range of screens and impellers are available to meet any process requirements.

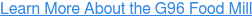

Food Milling Application Examples

Heat-sensitive, sticky and difficult materials can be size-reduced continuously at a high capacity without excessive heat build-up or screen blockage.

The Quadro® Comil® can be used for the reclaim of snack foods such as candies, cream-filled wafers, chocolate bars, cookies, granola bars and chewing gum. Anything that does not meet the quality control measures can be reprocessed and reduced back to powder for recirculating and reuse. The Comil® doesn’t generate excessive heat, which makes it particularly suitable for the reclaim of chocolate based products, where heat would denature the chocolate and affect its flavor and texture, resulting in scrap.

It can also be used to deagglomerate or delump sticky, hot cooked cereal to uniform pieces prior to flaker and dryer, and powders such as sugar, starch, flour, gelatin and cocoa.

Other food processors use the Comil® to fine-tune the bulk density of various powders to assist in reducing the volume of the powder prior to transportation.

Introducing the G96 Food Mill

The new G96 Food Mill is added to the Quadro portfolio and offers a cost effective, fast delivery time solution with an attractive ROI.

Designed for food processing and milling, the G96 Food Mill harnesses the tried and trusted Comil® technology. With a range of screens & impellers, it is possible to select the right combination to reach target PSDs, which enables flexibility in production changeovers.

It has an easy-clean design and is designed to be low maintenance. With inbuilt operator safety features and user-friendly controls, this mill enables a fast set up.

Download the brochure to find out more.

If you would like to find out how the Quadro team might be able to optimize your food milling process, please do get in touch.

Related Articles: