BENEFITS

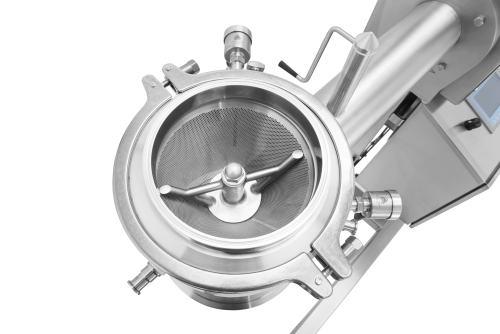

The Underdriven Cone Mill Comil® Series

High-capacity throughput cone mill with a compact design.

The Quadro® Comil® Underdriven Series has a compact, inline design with a short head height which allows for easy integration into powder milling and processing environments. It offers productivity improvements from world-leading technology.

With a small footprint, inline design, and extremely short head height it can be easily integrated into processing environments where space is limited. A large-diameter infeed and “straight-through” housing promote unhindered inline product flow for quicker discharge, and therefore higher throughput, improving productivity.

Available in five models, the Underdriven Comil® is scalable in capacity from several ounces (grams) to 35,000 lb/hr (15,900 kg/hr). The innovative spacerless design allows for quick changeover of impellers and screens. Plus, specialized tooling is available to meet all process requirements including handling heat-sensitive products.

We can help you choose the right screen and impeller.

Suitable for:

SLS U5 - Underdriven Comil®

LAB-SCALE CONICAL MILLING

High-performance lab-scale conical milling.

- Milling efficiencies ensure the highest percentage of product on-spec (up to 30% improvement vs other conical mills).

- Reduced heat generation at high throughput capacities.

- Accurate PSD (Particle Size Distribution) controllability.

- Efficient product processing or nearly 100% product recovery.

- Available in the SLS - Scalable Lab SystemTM processing platform - ideal for testing.

Features at a glance

- U5 Comil® conical mill head.

- Inline sanitary clamp design simplifies installation.

- Superior containment, with OEL levels under 1 µg/m3.

ENQUIRE

%20(1).webp)

1x

SCALE-UP FACTOR

Lab-Scale

WET 375Q (9.5MM) kg/hr

200 kg/hr

DRY 094R (2.4MM)

50 kg/hr

DRY 040G (1.0MM)

0.5 (375) HP (kW)

MOTOR

SDx™ U10x - Underdriven Comil®

CONICAL MILLING

Mid-range conical milling capacities

- Ideal for pilot-scale or mid-range capacity throughputs.

- Milling efficiencies ensure the highest percentage of product on-spec (up to 30% improvement vs other conical mills).

- Reduced heat generation at high throughput capacities.

- Accurate PSD (Particle Size Distribution) controllability.

- Efficient product processing for nearly 100% product recovery.

Features at a glance

- U10 Comil® conical mill head.

- Inline sanitary clamp design simplifies installation.

- Superior containment, with OEL levels under 1 µg/m3.

ENQUIRE

%20(1)%20(1).webp)

<1 kg to 100 kg/hr

SCALE-UP FACTOR

450 kg/hr

WET 375Q (9.5MM)

400 kg/hr

DRY 094R (2.4MM)

100 kg/hr

DRY 040G (1.0MM)

2 (1.5) HP (kW)

MOTOR

SDx™ U20x - Underdriven Comil®

PRODUCTION-SCALE MILLING

Efficient production-scale mill

- Milling efficiencies ensure the highest percentage of product on-spec (up to 30% improvement vs other conical mills).

- Reduced heat generation at high throughput capacities.

- Accurate PSD (Particle Size Distribution) controllability.

- Efficient product processing for nearly 100% product recovery.

- Available in the exchangeable heads processing platform SDx™ Series.

Features at a glance

- U20 Comil® conical mill head.

- Inline sanitary clamp design simplifies installation.

- Wide range of screens & impeller choices to suit every application.

- Superior containment, with OEL levels under 1 µg/m3.

ENQUIRE

10x

SCALE-UP FACTOR

2250 kg/hr

WET 375Q (9.5MM)

2000 kg/hr

DRY 094R (2.4MM)

500 kg/hr

DRY 040G (1.0MM)

5 (4) HP (kW)

MOTOR

High-Energy Comil® H20

HIGH-ENERGY MILLING

Features at a glance

- Unparalleled size reduction. Performance 30 - 70% finer PSDs

- Ability to control & shift PSD targets for coarser or finer results.

- Easy to clean thereby reducing changeover times.

- Contained milling OEL containment levels <1 μg/m3.

ENQUIRE

5 kW

POWER

150-500 kg/h

CAPACITIES

200 mm

SCREEN DIAMETER

Accreditations

As well as meeting the requirements of cGMP, we want to ensure that the machines we develop are well-designed and safe for the user, so we follow a variety of industry-specific directives.

All Quadro products are designed and manufactured in a facility with an ISO 9001:2015 accredited Quality Management System.

The scope of this Quality Management System applies to all processes and activities which are controlled, managed, and executed by employees within Quadro Engineering.

The current Certificate of Registration, reference Certificate No: CERT-0123530, was issued by SAI Global and is effective until September 2, 2024.

ATEX compliant milling equipment

We offer a complete selection of ATEX and UKEX certified mills that meet the European Union directives and UK Safety Regulations for products used in potentially explosive atmospheres.

Our equipment is designed to handle the toughest milling applications, which is why professionals around the world choose Quadro®. With models specifically designed to meet Ex Zone 0,20 (1GD) or 1/21 (2GD) requirements, we provide the most comprehensively safe mills in the industry.

All equipment destined for Europe is CE-marked and UKCA-marked for Great Britain. It comes with an EU or UK Declaration of Conformity or Declaration of Incorporation. European equipment is certified to comply with the Machinery Directive 2006/42/EC, the Low Voltage Directive 2014/35/EU, and the Electromagnetic Compatibility Directive 2014/30/EU. British equipment is certified to comply with the 2008 Supply of Machinery (Safety) Regulations, 2016 Electromagnetic Compatibility Regulation, and the 2016 Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres regulations.

Our equipment is designed to meet a variety of international safety standards, ensuring that whichever country you are in, we can certify compliance.

Our Range of Mills and Processing Equipment

We offer a wide range of solutions that provide reliable and repeatable results.

When you invest in Quadro® Powder Processing and Milling Technology you get more than just superior engineering and quality, you get access to our team of experts who will ensure you achieve your objectives.

Related Resources

- The Benefits of an Underdriven Cone Mill (Conical Mill)

- How to Choose a Conical Mill

- Best Practice and Guidance - Particle Size Reduction Mills and Sizing Equipment

- Quadro® Comil® | High-Efficiency Milling

- Replacing an Oscillating Granulator With a Comil®

- Pharmaceutical Milling Applications For The Quadro® Comil® Conical Mill

- How Does the SDx™ U20x Comil® Compare to the Classic U20 Quadro® Comil®

- Choosing the Correct Mill Screen for Your Bulk Powder Solids

- Benefits of Wet Milling Prior to Drying Pharmaceutical Powders