THE SDX™ SERIES

Production-Scale Milling & Screening

Introducing our next-generation innovation which brings together our leading milling and sifting technology from Quadro & Fitzpatrick. The SDx™ Series offers customers superior production-scale milling and screening capabilities.

The SDx™ Series is available to purchase as a standalone format of the U20x Comil®, D6Ax Fitzmill™ or the S20x FlexSift, or alternatively, multiple heads can be purchased to be used on the one base. These heads can be quickly interchanged when the SMARTdetect™ technology is included in the package.

The SDx™ Series platform will not only replicate the results of your current Comil®, Fitzmill™ or FlexSift, but enhance them. Improved housing designs enable easier cleaning and a greaseless gearbox reduces the risk of batch contamination and lowers the operating temperature. With an extensive range of screens and tooling, PSD and throughput targets can be more readily achieved.

By using multiple heads on one base unit, there is a lower cost of purchase and upkeep. The SMARTdetect™ technology in the control panel recognizes which head is installed and adjusts the RPM automatically, no need to spend time in set-up, rest assured that the equipment is set and ready to go.

Suitable for:

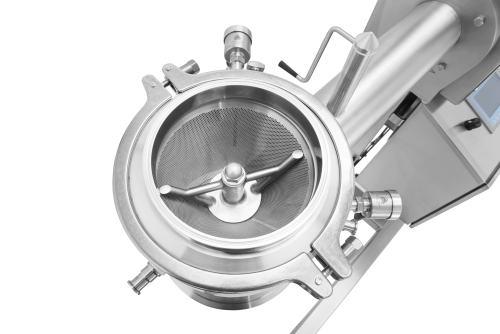

U20x Comil®

CONICAL MILLING

High-performance conical milling

Conical milling is one of the most popular milling methods and within the SDx™ Series, the U20x Comil® is frequently chosen as it produces high-quality results with repeatable and predictable particle size distributions (PSDs). The simple, modular design makes it easy to use and integrate with upstream and downstream equipment.

Not only is there a variety of screens available, but the U20x is compatible with legacy screens from the U20 saving on tooling costs. If throughput improvements are required, the exclusive High-Efficiency capacity screens with our proprietary design, offer up to 50% average capacity increase. Results achieved with the Classic U20 are replicated and enhanced with the new U20x head.

The unique greaseless sanitary gearbox offers batch reliability by mitigating the risk of contamination and lowering the operating temperatures which protects the powder.

Features at a glance

- Easy removal and assembly of head

- Tapered upper housing aids cleanability

- Greaseless gearbox

- Hazardous package for ATEX and XP

- Range of screens and impellers help attain PSD targets

- Scalable to the SLS Lab-Scale and Pilot-scale models

- Capable of CIP and SIP

ENQUIRE

up to ~2000 kg/hr*

CAPACITY

5.6 kW (7.5 HP)

POWER

<75 dB

NOISE

PSD target & set-up.

S20x FlexSift

DELUMPING & SCREENING

In-line security screening

The S20x FlexSift is frequently chosen for efficient deagglomeration or security screening. The simple, in-line, modular design makes it easy to integrate.

One unit can replace 3-7 traditional vibratory sifters whilst achieving similar capacities. What’s more, when compared to similar technologies the S20x can deliver 40-50% more capacity thanks to the unique screen designs and can meet OELs <1ug/m3.

The unique greaseless sanitary gearbox offers batch reliability by mitigating the risk of contamination and lowering the operating temperatures which protects the powder. With a variety of screens available, it is easy to achieve production targets.

Features at a glance

- Easy removal and assembly of head

- Tapered upper housing aids cleaning

- Capable of SIP

- Greaseless gearbox

- Hazardous package for ATEX & XP

- Scalable to the SLS Lab-Scale and Pilot-Scale models

ENQUIRE

%20(1).webp)

up to 10000 kg/hr*

CAPACITIES

5.6 kW (7.5 HP)

POWER

<75 dB

NOISE

PSD target & set-up.

D6Ax FitzMill™

HAMMER MILLING

Superior particle size reduction

When processing APIs, polymer-based hot melt extrusions and dry oral solid dosage powders, hammer milling could be the answer. Within the SDx™ production-scale platform, the D6Ax FitzMill™ is chosen as it offers maximum efficiency with minimum product retention, producing higher yields, lower milling temperatures and high throughputs.

The simple, 4-piece design of the chamber ensures complete access to all product contact surfaces for cleaning and eliminating contamination concerns, assuring 100% cleaning verification. The head is easily removed and installed onto the shaft for cleaning.

A variety of infeed chambers are available and include a cooling infeed for heat-sensitive products.

Features at a glance

- Easy removal and assembly of head

- 100% access to all head surfaces

- Hazardous package for ATEX and XP

- Range of screens help attain PSD targets

- Scalable from the SLS lab-scale model

ENQUIRE

.webp)

up to 1000 kg/hr*

CAPACITY

5.6 kW (7.5 HP)

MESH SIZE min

<80 dB

NOISE

PSD target & set-up.

CONTACT OUR TEAM

Looking for the Right Production-scale Mill?

Maintain low upkeep costs and improve efficiency with fast and simple head changover with the SDx Production Scale platform. Let the milling experts help you find the right solution for your application. Complete the form below to request a call back from a milling expert.

Gallery

IN DETAIL

SDx™ Series - Production Capacity Milling

Discover why Quadro has become the manufacturer of choice to fulfill multiple materials sizing requirements across a range of applications.

Accreditations

As well as meeting the requirements of cGMP, we want to ensure that the machines we develop are well-designed and safe for the user, so we follow a variety of industry-specific directives.

All Quadro products are designed and manufactured in a facility with an ISO 9001:2015 accredited Quality Management System.

The scope of this Quality Management System applies to all processes and activities which are controlled, managed, and executed by employees within Quadro Engineering.

The current Certificate of Registration, reference Certificate No: CERT-0123530, was issued by SAI Global and is effective until September 2, 2024.

ATEX compliant milling equipment

We offer a complete selection of ATEX and UKEX certified mills that meet the European Union directives and UK Safety Regulations for products used in potentially explosive atmospheres.

Our equipment is designed to handle the toughest milling applications, which is why professionals around the world choose Quadro. With models specifically designed to meet Ex Zone 0,20 (1GD) or 1/21 (2GD) requirements, we provide the most comprehensively safe mills in the industry.

All equipment destined for Europe is CE-marked and UKCA-marked for Great Britain. It comes with an EU or UK Declaration of Conformity or Declaration of Incorporation. European equipment is certified to comply with the Machinery Directive 2006/42/EC, the Low Voltage Directive 2014/35/EU, and the Electromagnetic Compatibility Directive 2014/30/EU. British equipment is certified to comply with the 2008 Supply of Machinery (Safety) Regulations, 2016 Electromagnetic Compatibility Regulation, and the 2016 Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres regulations.

Our equipment is designed to meet a variety of international safety standards, ensuring that whichever country you are in, we can certify compliance.

Our Range of Mills and Processing Equipment

We offer a wide range of solutions that provide reliable and repeatable results.

When you invest in Quadro Powder Processing and Milling Technology you get more than just superior engineering and quality, you get access to our team of experts who will ensure you achieve your objectives.

Related Resources

- How Does the SDx U20x Comil® Compare to the Classic U20 Quadro® Comil®

- How to Mill Powders and Granules to the Ideal PSD Without Heat

- Pilot-scale and Mid-size Milling With the SDx™ Series

- Interchangeable Powder Milling and Sizing System

- Interchangeable Milling & Processing System featured at Virtual Expo

- Advantages of a Greaseless Gearbox for Milling and Sizing Equipment

- Choosing the Correct Mill Screen for Your Bulk Powder Solids