BENEFITS

Milling & Screening Platform for Mid-Sized Capacities

Presenting the next phase of our cutting-edge product development in powder processing and size reduction. The industry's most progressive mid-sized milling and screening platform offering two pilot-scale processing solutions on a single, common drive.

Flexible and easy to migrate from the lab, this model of the SDx™ Series provides the easiest path from research & development through to full production - sitting between the SLS - Scalable Lab System™ and the SDx™ Series production-scale powder milling & screening platforms. This is also ideal for Customers who have smaller-scale production runs.

This complements the Fitzpatrick & Quadro range of exchangeable milling and screening platforms.

Easily navigate between the Quadro® Comil® and Quadro® FlexSift security screener as the SMARTdetect™ technology will recognize the head and automatically make RPM modifications, affording the ability to change heads in seconds.

Exceptional value for your investment - two individual functionalities on a single platform, providing the lowest long-standing cost when compared to the purchase of individual units.

Suitable for:

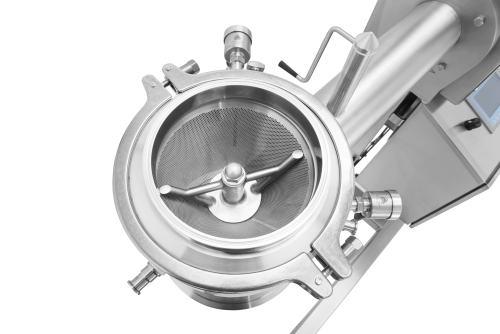

U10x Comil®

CONICAL MILLING

Benefits of the U10x Comil:

- Results obtained with the pilot-scale Classic U10 are duplicated and enhanced with the new and improved U10x.

- The greaseless gearbox reduces the risk of contamination and lowers the operating temperature.

- Achieve tighter particle size distributions (PSDs) with 20-40% more on-target.

- Patented high-efficiency screens offer up to 50% increased capacity and up to 30% lower temperatures (product dependent).

- Compatible with Classic U10 screens & impellers - saving on tooling requirements.

Features at a glance

- Greaseless Gearbox

- High-Efficiency Screen Options

- CIP Improvements

- Compatible With Classic U10 Tooling

- Lab-Scale Model - SLS Range

- Production-Scale Model - SDx Range

ENQUIRE

%20(1)%20(1).webp)

400 kg/hr

CAPACITIES

2.2 kW (3 HP)m

POWER

<75 dB

NOISE

S10x FlexSift

SECURITY SCREENING

Benefits of the S10x FlexSift:

- Security screening; one unit substitutes for multiple traditional vibratory sifters while achieving comparable capacities.

- Best-in-class functionality with 40%–50% more capacity vs. like technologies.

- Optimum capacity range as compared to any other centrifugal security screener in the market.

- Greaseless gearbox eliminates the risk of contamination.

Features at a glance

- Greaseless Gearbox

- Lab-Scale Model - SLS Range

- Production-Scale Model - SDx Range

ENQUIRE

5000 kg/hr

CAPACITIES

2.2 kW (3 HP)

POWER

<75 dB

NOISE

Gallery

Accreditations

As well as meeting the requirements of cGMP, we want to ensure that the machines we develop are well-designed and safe for the user, so we follow a variety of industry-specific directives.

All Quadro products are designed and manufactured in a facility with an ISO 9001:2015 accredited Quality Management System. The scope of this Quality Management System applies to all processes and activities which are controlled, managed, and executed by employees within Quadro Engineering.

ATEX compliant milling equipment

We offer a complete selection of ATEX certified mills that meet the European Union directives for products used in potentially explosive atmospheres.

Our equipment is designed to handle the toughest milling applications, which is why professionals around the world choose Quadro. With models specifically designed to meet Ex Zone 0,20 (1GD) or 1/21 (2GD) requirements, we provide the most comprehensively safe mills in the industry.

All equipment destined for Europe is CE-marked. It comes with an EU Declaration of Conformity or Declaration of Incorporation. European equipment is certified to comply with the Machinery Directive 2006/42/EC, the Low Voltage Directive 2014/35/EU, and the Electromagnetic Compatibility Directive 2014/30/EU.

Our equipment is designed to meet a variety of international safety standards, ensuring that whichever country you are in, we can certify compliance.

Our Range of Mills and Processing Equipment

We offer a wide range of solutions that provide reliable and repeatable results.

When you invest in Quadro Powder Processing and Milling Technology you get more than just superior engineering and quality, you get access to our team of experts who will ensure you achieve your objectives.

Related Resources

- Pilot-scale and Mid-size Milling With the SDx™ Series

- How to Mill Powders and Granules to the Ideal PSD Without Heat

- How Does the SDx™ U20x Comil® Compare to the Classic U20 Quadro® Comil®

- Advantages of a Greaseless Gearbox for Milling and Sizing Equipment

- Choosing the Correct Mill Screen for Your Bulk Powder Solids