BENEFITS

Ultra-Fine Powder Grinding

The F10 fine grind mill is an advanced fine powder grinding machine, producing the highest percentage within the target PSD of any existing fine milling technology.

For D50 milling in the 5–45 micron (< 325 U.S. standard mesh) range, the Quadro® Fine Grind F10 delivers unsurpassed particle size consistency and maximum on-spec yield. Used to size-reduce diverse materials and those traditionally considered to be difficult to grind such as APIs, excipients, fine chemicals, nutraceuticals and high-value flavors and fragrances.

Learn more about our fine powder grinder.

Equipment for Fine Powder Grinding

This ultra-fine powder grinding mill yields the highest percentage of fine particles within the target of any fine milling technology with up to 40% improvement in results when compared to other milling options. Competitive technologies typically don’t incorporate two-stage size reduction technology like the Fine Grind, so they are simply not equipped to replicate the Quadro® Fine Grind’s exceptionally narrow particle size distribution (PSD) curves.

Suitable for:

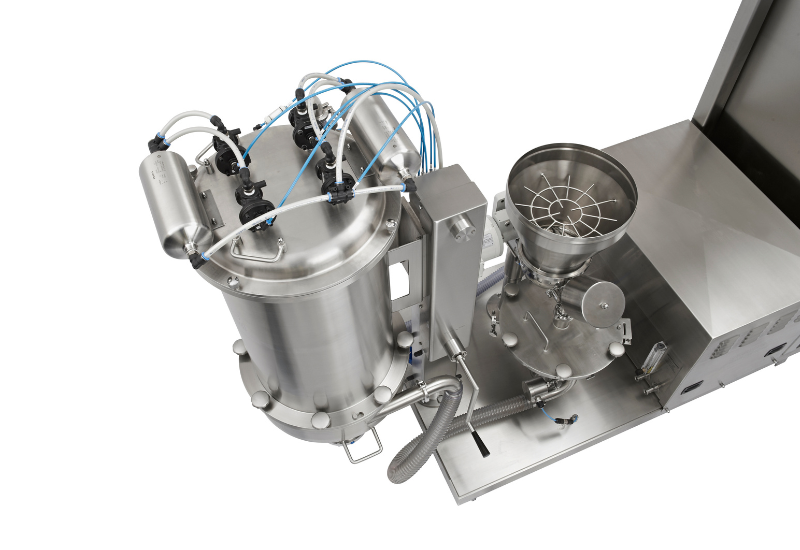

F10 Fine Grind

FINE POWDER GRINDER

The Quadro® Fine Grind Model F10 is a turnkey, automated, stand-alone process system, making it the ideal addition to your production line when quick and efficient process integration is paramount. The exclusive all-in-one platform design eliminates the need for ancillary equipment.

Features at a glance

- High yields & reduced waste ensures manufacturers increase profitability.

- Narrow Particle Size Distribution curves for D90 targets in the 20 – 60 µm range.

- Easy-clean design enables rapid switching between batches with minimal downtime.

- Low heat production, reduced noise output and low power/air consumption.

- Compact footprint & convenient mobile design.

- Simple connection to existing collection devices.

ENQUIRE

7.5 kW

POWER

10 - 200 kg/h

CAPACITIES

3600 - 8400

RPM

Gallery

Accreditations

As well as meeting the requirements of cGMP, we want to ensure that the machines we develop are well-designed and safe for the user, so we follow a variety of industry-specific directives.

All Quadro products are designed and manufactured in a facility with an ISO 9001:2015 accredited Quality Management System.

The scope of this Quality Management System applies to all processes and activities which are controlled, managed, and executed by employees within Quadro Engineering.

The current Certificate of Registration, reference Certificate No: CERT-0123530, was issued by SAI Global and is effective until September 2, 2024.

ATEX compliant milling equipment

We offer a complete selection of ATEX and UKEX certified mills that meet the European Union directives and UK Safety Regulations for products used in potentially explosive atmospheres.

Our equipment is designed to handle the toughest milling applications, which is why professionals around the world choose Quadro. With models specifically designed to meet Ex Zone 0,20 (1GD) or 1/21 (2GD) requirements, we provide the most comprehensively safe mills in the industry.

All equipment destined for Europe is CE-marked and UKCA-marked for Great Britain. It comes with an EU or UK Declaration of Conformity or Declaration of Incorporation. European equipment is certified to comply with the Machinery Directive 2006/42/EC, the Low Voltage Directive 2014/35/EU, and the Electromagnetic Compatibility Directive 2014/30/EU. British equipment is certified to comply with the 2008 Supply of Machinery (Safety) Regulations, 2016 Electromagnetic Compatibility Regulation, and the 2016 Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres regulations.

Our equipment is designed to meet a variety of international safety standards, ensuring that whichever country you are in, we can certify compliance.

Our Range of Mills and Processing Equipment

We offer a wide range of solutions that provide reliable and repeatable results.

As well as Fine Powder Grinding, Quadro Engineering offer milling and particle sizing solutions that provide reliable and repeatable results.