ADVICE ON MILLING TECHNOLOGY AND PARTICLE SIZE REDUCTION MACHINES

Particle Size Reduction Mills and Sizing Equipment

The definitive guide to choosing milling and sizing equipment to reach a desired particle size distribution.

2 Min Read Time

Experts in Particle Size Reduction and Milling Equipment

With nearly 50 years of expertise in milling and particle size reduction, Quadro delivers leading process innovation for a range of industries.

With nearly 50 years of experience, the Quadro Engineering team supports leading manufacturers in a range of industries to achieve precise, safe, and efficient particle size reduction. Our equipment ensures consistent results, meeting strict FDA standards for every batch.

Over the decades, Quadro's industry leadership has been reaffirmed with every new product generation. We use this expertise to develop the best solutions and create market-leading wet and dry milling Equipment. To help you answer some common questions and support your next steps in powder processing, we've prepared an article of our frequently asked questions.

1.1 WHAT IS A CONICAL MILL

What is a Comil?

Comils are typically used for size reduction and deagglomeration or delumping of powders and granules.

The Quadro Comil is the original cone mill (conical screen mill) for uniform particle size reduction, deagglomeration and wet mass milling. First developed and engineered in 1976, the Comil has become the standard across many industries globally for size reduction and deagglomeration.

Applications for conical mills can range from sizing wet granulated particles before drying, sizing dry granules before tableting, delumping dry detergent during production, deagglomeration, and reclaiming off-spec products such as broken tablets and cookies.

1.2 HOW A CONICAL MILL WORKS

How Does a Comil Work?

Conical milling is widely used in the pharmaceutical, food, and chemical sectors to reduce particle size and eliminate clumps in powders and granules.

A conical mill uses centrifugal force to reduce material size. Material enters through a feed hopper, where a rotating impeller pushes it against a fixed conical screen. Fine particles pass through the screen and are collected, while larger ones remain in the mill for further processing.

This method reliably produces particles as fine as 180µm while generating minimal dust and heat. Its gentle milling action and rapid discharge of correctly sized material help achieve consistent, controlled particle size distributions. The Quadro® Comil® was the first of its kind, and has remained the industry standard in conical milling for nearly half a century.

1.3 OVERDRIVEN COMILS

What are the Benefits of an Overdriven Comil?

Low cost of ownership, minimized dust creation and scalable results are just a few of the key benefits of our Overdriven Comil.

The Overdriven Comil is the original conical mill, introduced by Quadro in 1976. This versatile mill supports a wide range of applications, including powder size reduction, deagglomeration, dispersion, separation, reclamation, and bulk density control. It delivers precise, repeatable particle size distribution, ensuring consistent product quality in every batch and is the simplest, most economical cone mill to operate and maintain. Learn more in this blog.

1.4 UNDERDRIVEN COMILS

What are the Benefits of an Underdriven Comil?

Enhance containment, consistency, and efficiency to drive reliable, scalable manufacturing performance with the Underdriven Comil.

Modern powder processing industries demand solutions that deliver precise, consistent results while maintaining operational reliability and safeguarding product integrity. The Underdriven Cone Mill represents an innovative approach, designed to address key challenges such as powder containment, batch-to-batch consistency, and efficient scale-up. Explore how the Underdriven Comil unlocks new levels of process control, helping manufacturers advance productivity, reduce downtime, and achieve superior material quality across a wide range of applications.

How to Select a Conical Mill

What should you consider when choosing a cone mill?

2.1 MILLING EFFICIENCY

How Can You Increase Productivity in Your Milling Process?

Maximize output and flexibility to meet dynamic manufacturing demands.

Today’s manufacturing landscape demands both operational efficiency and the ability to adapt quickly to evolving product requirements. Achieving these goals hinges on process technologies that deliver consistent results while supporting compliance, containment, and throughput. Conical mills enable precise particle size control, reduced product loss, and seamless integration into diverse processes. Explores how advanced cone mill technology can elevate productivity and provide manufacturers with the flexibility required to succeed in a highly regulated, fast-paced industry.

2.2 MILLING HEAT-SENSITIVE MATERIALS

How to Choose the Correct Mill Screen and Impeller for Your Product

To ensure high-performance milling, you must choose the correct conical mill screen for your application, especially for heat-sensitive materials.

When milling heat sensitive products, it can be difficult to stay within the strict temperature parameters, especially for heat-sensitive materials, when you have high output ambitions.

To increase output with efficient milling practices, you need to find the optimum balance between size reduction and heat generation. An increase in temperature can lead to product degradation, reduced ingredient effectiveness, and in extreme cases waste. Learn more about milling heat-sensitive materials.

PARTICLE SIZE CARD

The Right Mill and Screen for Your Desired PSD

Achieving the desired target particle size at a tight particle size distribution is vital when producing a quality end product, no matter what industry you operate in.

The correct PSD can affect factors like drug efficacy and tablet integrity for pharmaceuticals, pigment coloration and safety in the chemical industry, and taste and texture for food products.

2.3 CLEANING TECHNIQUES FOR MILLING

Cleaning Best Practice for Pharmaceutical Milling & Particle Size Reduction

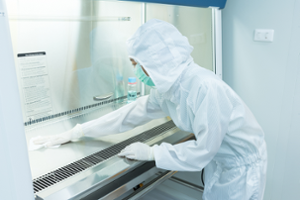

When manufacturing food and pharmaceutical products, strict cleaning processes are required to prevent contamination and comply with regulations.

Consistent, thorough cleaning of milling and particle sizing equipment is essential for maintaining product quality, meeting regulatory standards, and minimizing the risk of contamination. Explore our recommendations for effective strategies and practical tips to improve cleaning processes and support compliance in your milling application.

2.4 INCREASING MILLING VOLUME

How to Scale Up to Larger Comil Units

How to create a manufacturing process that continues to meet growing production demand.

As manufacturing operations continue to evolve, scaling up powder processing efficiently is crucial to maintain quality and throughput. With decades of innovation in cone milling technology, Quadro’s larger Comil units are engineered to support increased batch sizes while preserving product integrity. Results achieved on our lab scale equipment can be repeated at larger volumes with our pilot and productino scale models. Discover how precise, scalable milling solutions can help your facility accommodate rising production requirements and meet today’s rigorous industry standards.

How to Choose the Right Mill for Your Application

One expert solution for a range of industries and applications.

3.1 MILLING PHARMACEUTICALS

The Importance of Milling in Pharmaceutical Manufacturing

Milling is a key process step that drives quality and consistency in pharmaceutical products.

Milling is crucial in pharmaceutical OSD and API manufacturing, directly impacting product uniformity, efficiency, and overall quality. Pharmaceuticals demand precise particle size control and exceptional cleanliness, which means powders must be homogeneous and maximize bioavailability. Explore how Quadro's advanced milling technology enables reliable, contamination-free size reduction to meet today’s stringent industry standards.

For OSD manufacturing processes that involve wet granulation, Quadro provides conical millign solutions as well as gentle sifting to support the whole process.

.webp)

3.2 MILLING NUTRACEUTICALS

Efficiently Reduce Particle Size in Nutraceutical and Food Manufacturing

Manufacturers of powder-based food and nutraceutical products need to ensure that materials flow through the production process efficiently.

To achieve this, most deploy some method of size reduction to process their dried powders into a specific form ready for downstream equipment. The reason for this is to create a powder product that is flowable, free from agglomerations and with the correct particle size distribution. Discover how The Quadro® Comil® and FlexSift help manufacturers ensure equally sized particles.

.jpg)

3.3 MILLING FOOD PRODUCTS

Conical Milling Solutions for Dairy Food Manufacturers

Discover how manufacturers of dairy products such as ice cream and yogurts are commonly looking for new ways to differentiate their existing product lines.

This often requires adding new, colorful, or uniquely flavored decorative toppings or inclusions within the recipe, which typically means handling irregularly shaped ingredients that are often heat-sensitive. Discover how the Quadro® Comil® offers the ideal solution for re-sizing particles without creating fines due to low speed and low energy conical milling.

CONTACT US

Innovative Milling Solutions

For over 40 years we have helped our customers find innovative milling and particle size reduction solutions across various industries. If you're interested in learning more about our market-leading wet and dry milling equipment, please get in touch.

.webp)