Conical milling is commonly used in the food and pharmaceutical industry where the primary goal is to increase surface area and improve the bulk density, powder flow, and tablet compressibility properties of an oral solid dosage (OSD) formulation. All of these aims are however not without challenges.

The Importance of Particle Size Distribution

Achieving the desired particle size distribution (PSD) for your powders and granules is essential in order to improve absorption rates, physical stability, dissolution rates, and bioavailability. However, many manufacturers overlook the importance of using a mill to achieve the ideal PSD in food and pharmaceutical production.

When it comes to size reduction using the milling method, there are various theories applied. In the case of using a Conical mill, the key factors are the "attrition" forces between the impeller and the screen, which are directly proportional to the impeller velocity. The selection and setup of the impeller and screen greatly influence these forces.

While the PSD achieved is determined by the screen and impeller selection, using the wrong screen or low-quality screens can result in unwanted heat generation, wide PSD curves, and an excessive amount of fines. This, in turn, leads to poor powder flowability and inconsistent tablet weight and/or dosage of the active ingredient.

Introducing the Patented High Efficiency Screens

To overcome these challenges, Quadro Engineering Corp & the Fitzpatrick Company, which are business units of IDEX Material Processing Technologies, have introduced a patented "High Efficiency" conical screen. These screens have been designed to address the issues associated with milling processes.

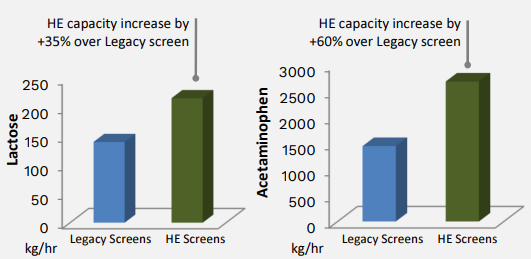

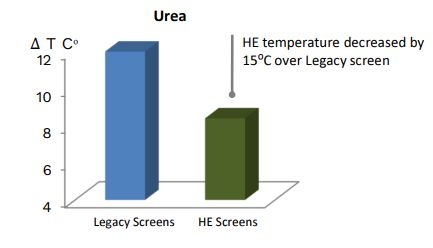

The use of High-Efficiency (HE) screens offers several benefits. Firstly, they can increase capacity by an average of 50%. The capacity improvement is directly proportional to the increase in the % open area of the screens. Secondly, these screens can decrease milling temperatures by as much as 10 to 15 degrees Celsius, reducing the risk of screen blinding and downtime, particularly for heat-sensitive powders. Finally, High-Efficiency screens can improve particle size distributions (PSDs) by reducing "span," resulting in reduced fines and overs. This improves powder flowability, enhances compaction performance, and ensures more consistent tablet weights and uniform dosages.

High-Efficiency Conical Milling with the SDx Series™

This new High-Efficiency conical screen is designed to work with the SDx Series™ – Smart Drive Exchangeable Platform. Still, it is also backward compatible with other underdriven Quadro production & mid-size/pilot-scale milling platforms.

INCREASED Capacity Potential

Unique High-Efficiency (HE) screens improve powder flow thus reducing product residence time inside the milling chamber. High-efficiency screens are available for round (R) and grater (G) screens for our SLS-U5, U10x (U10) and U20x (U20) models.

Benefits

- High-efficiency (HE) screens average a 50% capacity increase.

- HE capacity improvement over Legacy screens is directly proportional to the % open area increase.

REDUCED Milling Temperatures Potential

The screen's hole pattern used on the High-Efficiency (HE) screens decreases product residence time inside the milling chamber resulting in lower milling temperatures.

Benefits

High-efficiency (HE) screens are capable of reducing milling temperatures by as much as 10 to 15 degrees Celsius. For heat-sensitive powders, this greatly diminishes the risk of screen blinding and downtime.

IMPROVED PSD Versatility Potential

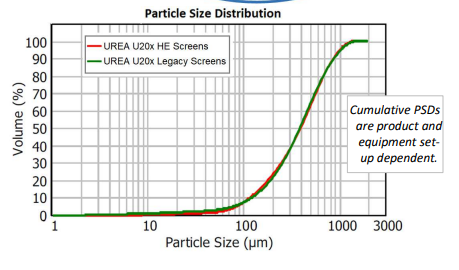

U20x can utilize both standard (Legacy) screens, but also the new patented high-efficiency (HE) screens.

High-efficiency screens can further improve PSDs (reduce ‘span’) yet remain within validated +/- limits. (see FDA guidelines).

Benefits

Reduced fines and overs result in better powder flowability to the tablet press, improved compaction performance, more consistent tablet weights, and uniform dosage.

Conclusion

Achieving the desired particle size distribution (PSD) is essential for the successful formulation of oral solid dosage (OSD) formulations in the food and pharmaceutical industry. Using a Conical mill and selecting the appropriate screen and impeller are crucial steps in the milling process. By utilizing the patented High-Efficiency conical screens, with their innovative patented screen-hole pattern, it has been proven that milling temperatures are reduced at the same time throughput capacities are increased, when compared to traditional screen designs. All without changing or shifting particle size distributions, thus ensuring validated processes and results remain unaffected.

Speak to our team

The Quadro Engineering team has many years of experience working with a range of applications, from food and nutraceuticals to the precise requirements of pharmaceutical OSD and API manufacturing. To learn more about our Particle Size Reduction Mills and Sizing Equipment please contact our team of milling experts.