Benefits of the Quadro® Fine Grind Model F10:

For effective fine particle size reduction and milling between 5 – 150 micron (<100 US standard mesh), the Quadro® Fine Grind Model delivers unsurpassed particle size consistency and maximum yield on-specification when size reducing materials such as API’s, excipients and fine chemicals. The Fine Grind delivers:

- A product recovery of +99%

- Narrow API PSDs (very tight spans)

- Unmatched particle size controllability

- Product collector filter efficiency of 99.997% over a 50-hour period

- Up to OEB 5 (<1µg/m3) containment

The Quadro® Fine Grind’s wide range of tooling, small footprint and mobile design provide unrivaled process flexibility. What’s more, its quick disassembly enables easy maintenance and cleaning. Additional advantages such as low heat, low noise and low power/air consumption, along with fully integrated controls, afford the optimum production tool.

The Quadro® Fine Grind Model F10 achieves tight particle size distributions with minimum fines and overs as compared to traditional methods. It provides advanced size reduction for superior performance and flexibility, an all-in-one powder fine grinding platform.

Fine Grind Features:

Milling Head - the heart of Quadro’s F10 Fine Grind Milling System utilizes two-stage size reduction technology. This revolutionary method ensures an extremely tight particle size distribution bell curve, time-after-time.

Product Feeder – the hopper’s easy-flow design with tapered sides ensures continuous and positive product feed availability. Feeder’s dual counter-rotating screw mechanism provides consistent lump-free product. Feed rates can be controlled to compensate for a wide range of products with varying characteristics.

Control Panel - user-friendly control panel incorporates an array of easy-to-use features, including a VFD to adjust milling speeds as dictated by in-feed material properties. The control panel is conveniently secured to a compact mobile platform which also houses the balance of ancillary equipment, all within an easy-to-access enclosure for maintenance and cleaning.

Product Collector – high-efficiency and easy-to-clean product collector system utilizes four EPTFE membrane filter bags with a 99.997% efficiency rate when tested with 100% silicate particulate (0.5µm median size for 50 hours).

Principle of Operation:

- Raw material is fed into the preliminary size reduction chamber where a rotating impeller imparts a vortex flow pattern to the incoming product.

- The additional lower chamber in the F10 complete with a second impeller leads to more consistent size reduction by means of inter-particulate acceleration. Size reduction occurs via the impact attrition mechanism.

- The milling chamber is water-cooled thereby contributing to the creation/maintenance of a more uniform and consistent particle size distribution. It also prohibits an operational hazard whereby the milling chamber would overheat.

- Through centrifugal acceleration, the product is directed to the screen surface ensuring optimal delivery into the action zone where size reduction takes place.

- Product is size reduced in the milling chamber’s action zone.

- Finished product is discharged from the milling chamber into the collection system.

The Quadro® Fine Grind Model F10 is a complete, automated, distinct process system which makes it the perfect solution for your production line when fast and effective process integration is vital. The exclusive all-in-one platform design eradicates the need for auxiliary equipment.

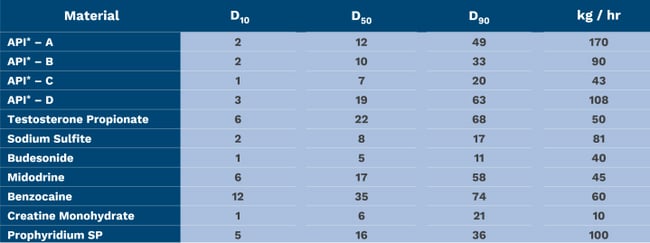

Proven Performance Reference Guide:

*APIs are proprietary information.

Available Options:

- Isolator Integration

- Vacuum Conveying Adaptors

- WIP (Wash-In-Place)

- Inert Applications

- ATEX / XP

- In-Line Analysis Ready

Summary of the Fine Grind Model F10 :

Quadro’s on-going efforts to innovate milling and powder processing technology in the field of size reduction are once again realized with the development of the Quadro® Fine Grind Model F10, offering the following:

- Savings - reduced downtime, space requirements, rapid product changeover and enhanced process efficiency (typical changeover in approximately 1 hour).

- Quick disassembly for maintenance, tooling change and cleaning.

- Low power consumption as compared to traditional mills (50% reduction in energy consumption versus traditional high impact mills).

- Low noise - soundproofing is not a necessity.

- Uniform grinding capabilities - higher yields on specification (+99% product yield).

- Wide tooling selection to meet all grinding needs.

- Complete stand-alone process system eliminates the need for costly ancillary equipment typically applied in traditional methods.

If high yields, reduced waste and increased profitability are key to the success of your process application requirements, consider the Quadro® Fine Grind Model F10. To find out more, download our Product Overview

Please also take a look at our existing Fine Grind blog on our website, posted in July, 2020.