The Quadro Comil - Proven for Pharmaceutical Milling

Pharmaceutical companies worldwide are successfully using the Quadro® Comil® for wet granulation mixes before drying, sizing after drying, granulating in the pre-compression stage, homogeneous mixing, conditioning, and dispersion of pigments in the manufacture of tablets.

Wet Granulation Sizing

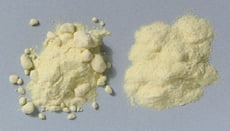

The Comil® is designed to take wet lumpy granulations and uniformly size them at very high capacities.

Sizing or de-lumping wet granulations ensures equally sized granules are introduced into driers, thus eliminating case hardening and helping granules to dry uniformly and more rapidly.

Uniform particle size distributions prevent fines and potentially un-even die-filling or sticking at the punches during tableting.

Double Compression

Direct compression blends are pre-compressed, granulated, then pressed into tablets. Ribbons from the roller compactor or slugs from pre-compression can be size reduced with a Comil® to granules with optimum particle size distribution.

Dried Granulation Sizing

The Comil® sizes dry granulation material to the optimum particle size distribution for efficient tableting.

Tablet/Capsule Reclaim

“Off-spec” tablets are size reduced for reclaim purposes. “Off-spec” capsules are broken into large pieces allowing for easy separation of powder from the gelatin pieces.

Ingredient Conditioning

Ideal for a broad range of de-lumping, mixing, finishing and milling.

Lump-free homogeneous dry ingredient blending. Low heat build-up and precise screen size ensure complete dispersion, at desired particle size.

The benefits of the Quadro Comil®

- Low dust

- Low noise

- Low heat

- Fewer fines

- Short changeover times

- High capacities

- Easy, fast cleaning

(Ref: AP16 Comil® Pharmaceutical Applications)

Learn more about Quadro's Pharmaceutical Milling Equipment

Quadro's Technology, Particle Processing, Particle Size Reduction, Mills and Milling Technology via our knowledge hub page, containing a range of useful articles and guides. Or to contact a member of the Quadro Engineering team please contact us.