Benefits

Delivering trusted Comil® performance, the Quadro® G96 Food Mill is purpose-built for the precise milling and deagglomeration of process-sensitive food ingredients.

Engineered specifically for the food sector, it combines decades of proven Comil® technology expertise. A tailored selection of screens will deliver milling to target PSDs, deagglomeration and delumping that leading manufacturers demand.

The G96 Food Mill is designed for flexibility— it can be easily adapted to suit different materials and installation requirements, fitting seamlessly into a wide range of production environments. With robust operator safety and intuitive operation, it drives production efficiency while minimizing downtime.

Supported by world-class engineering and aftersales service, we ensure fast commissioning and ongoing peace of mind for your team.

Applications

Size Reduction

Deagglomeration

- Breakfast cereals

- Chocolate/candy bars

- Baked goods (bread, cake, muffins)

- Hard candies/cough drops

- Granola/energy bars

- Potato chips, nachos, taco shells

- Cocoa (coarse grind)

- Protein fractions

- Soft nuts (peanuts)

- Dehydrated fruit (coarse grind)

- De-skinned garlic cloves

- Bacteria cultures

- Finish blending of high fat powder mixes

- Hot cooked cereals

- Fruits

- Frozen vegetables

- Dried bean cakes (tofu)

- Dairy & non-dairy bases (bulk density tuning)

- Granola

- Chocolate/vanilla/bread crumbs

- Sugar

- Finish blending of spices

G96 Food Mill Comil®

GENTLE SIZE REDUCTION OF FOOD INGREDIENTS

Reassuring Comil® performance for the milling and deagglomeration of process-sensitive food materials.

- Production efficiency from easy-clean design & low maintenance requirements

- Flexibility in usage by using a variety of screen types to match milling target PSDs, specific food materials & applications

- Operator safety due to inbuilt grids as standard & interlocked swing-away discharge shrouds

- Tried and tested technology with decades of experience

- Quality aftercare with OEM spares readily available

Features at a glance

- Industry standard stainless steel material & finishes, FDA compliant seals

- Utilizes the same screens and impellers as 196 Comil® and classic G96 Comil®

- Infeed inlet options - handfeed funnel or straight spigot

- Simple controls compliant to CE safety standards or choose to supply your own

- Motor options (see brochure for more details)

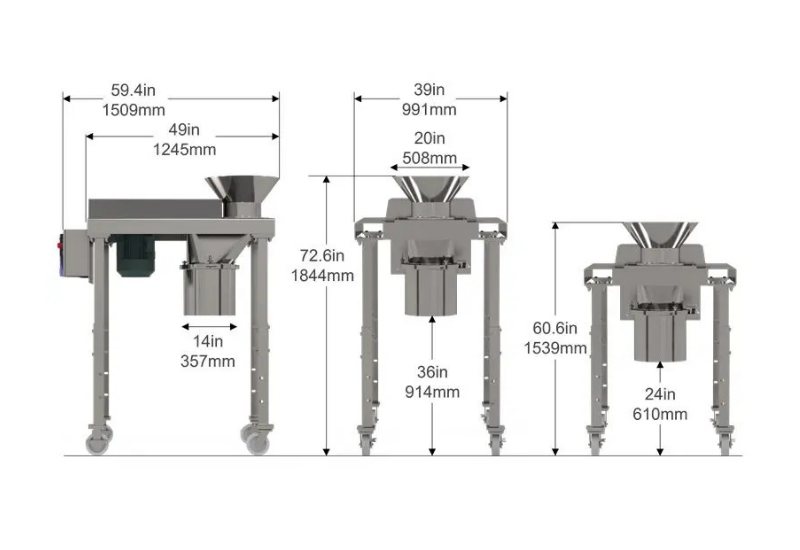

- Adjustable leg heights with casters, fixed height sanitary legs with casters, or available without legs

450 - 1800 RPM

SPEED RANGE

230/460/575 V

MOTOR POWER OPTIONS

Accreditations

We want to ensure that the machines we develop are well-designed and safe for the user, so we follow a variety of industry-specific directives.

Our equipment complies with current Good Manufacturing Practices (GMP) as generally guided by FDA (Federal Regulations Title 21). All equipment is designed and manufactured with hygiene and sanitation as primary considerations, and complies with the following material standards:

- (EC) 1935/2004 “Materials and articles intended to come into contact with food”

- (EC) 2023/2006 “Good manufacturing practice for materials and articles intended to come into contact with food”

- FDA 21 CFR 177.2600 “Rubber Articles Intended for Repeated Use”

- FDA 21 CFR 177.1550 “Perfluorocarbon Resins”

All equipment destined for Europe is CE and UKCA-marked and comes with either a EU/UK Declaration of Incorporation or Declaration of Conformity. European equipment is certified to comply with:

- Machinery Directive 2006/42/EC

- Low Voltage Directive 2014/35/EU (for machines supplied with a motor and controls)

- Electromagnetic Compatibility Directive 2014/30/EU (for machines supplied with a motor and controls).

British equipment is certified to comply with:

- Supply of Machinery (Safety) Regulations 2008

- Electromagnetic Compatibility Regulations 2016 (for machines supplied with a motor and controls)

- Electrical Equipment (Safety) Regulations 2016 (for machines supplied with a motor and controls).

Gallery

Related Products

Scalable Lab System

Five powder milling & processing solutions in one platform for effective laboratory-scale research & development.

Explore

Explore

SDx Mid-Size

Effective, reliable, and efficient powder milling technology at pilot scale, with results that can be scaled up to production.

Explore

Explore

SDx Production-Scale

Innovative sifting and size reduction technology, offering multiple powder processing solutions on one intuitive platform.

Explore

Explore

USEFUL INFORMATION

Matcon Powder Handling Systems

Complete powder handling equipment solutions for manufacturers of food flavorings and spices.

Equipment for material handling, formulation, blending and powder discharge, solving common powder handling problems.

If you need advice and/or powder handling equipment for the food and flavorings industry, get in touch with Matcon, another business unit of IDEX Material Processing Technologies.

Related Resources

- Quadro® Comil® | High-Efficiency Milling

- Choosing the Correct Mill Screen for Your Bulk Powder Solids

- Milling Nutraceuticals, Functional Foods and Nutritional Supplements

- Deagglomeration and Delumping - Overcome Raisin Agglomeration

- Milling Dairy Powders for Chocolate, Nuts, Dried Fruit and Cereals

- Conical Milling for Food Ingredients